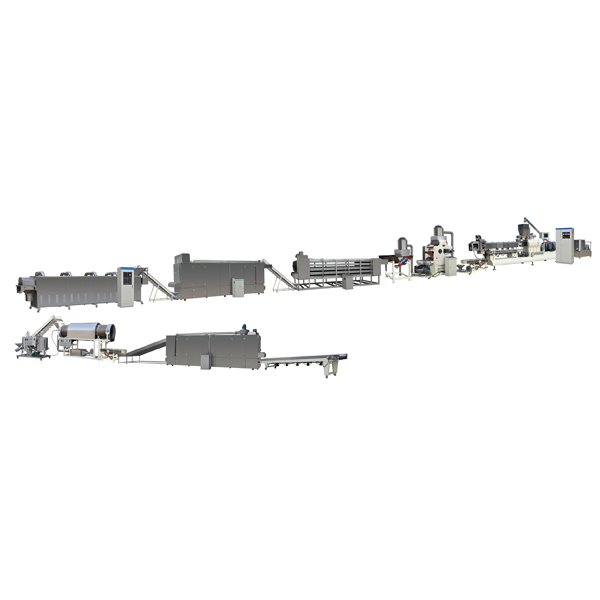

The Corn Flakes Making Machine Series — HWM

Cereal or Corn Flakes Making Machine Series:

For the manufacturing of maize flakes and delicious flavoring flakes

Powder Mixer Machine:

The Powder Ingredients in certain pre-set formula are blended in the Powder Mixer Machinie and then routinely deliver into the line mixer machine to obtain a dough.

Food Extrusion Machine:

The powders are moisturized into the blending container. The dough is moved into the Food Extrusion Machine in which the food cooking phase occurs. The combination between the accurate heat range control system and the proficient twin screw technology enables a reliable gelatinisation process that cannot destroy the nutritious structure of starches. They are the essential factors to influence the excellent performance of the finish foodstuff. The unit featires an exceedingly high versatility since it is feasible to adjust extensively the process heat range and dwelling time: it is very easy to handle mixtures made up of potatoes and also challenging to cook cereals consistently attaining the best gelatinisation.

Rotating Slicing:

The sizzling extrudates are sliced at same length by a rotating slicer into tiny cylinders.

Cereal Flaking:

The semi-foodstuff goes through Cereal Flakes in which the foodstuff is compressed and obtains the conventional breakfast cereal style.

Pre-Drying Process:

The cereal flakes experiences the first exterior drying process prior to baking.

Baking Process:

The foodstuff is expanded by way of a baking process for couple of seconds with large heat air flow on shaking steel belt. The baking is split into two phases: first phase the foodstuff experiences a sizzling air flow creating the foodstuff expand; the second phase with lesser variables is to obtain the foodstuff gilding.

Delicious Flavoring Syrup Preparation Stage:

This device is applied for the preparation of the sugar to be carried to the flavouring unit. The foodstuff can be covered with delicious chocolate or some other delicious syrups. The device is constructed of a couple of drums thermally insulated to keep the syrup at high temperature conditions avoiding it from becoming solid: the first drum is applied to prepare the syrup, the second drum is for storage. A spraying unit take the syrup onto the flavoring drum.

Flavoring:

The foodstuff is painted with syrup in a tank which is lying for cleaning functioning. The drum rate is adjustable to modify dwelling time.

Drying Out Processing:

The sprayed foodstuff is delivered to a dryer unit to lessen wetness and for crystallization.

Cooling:

The foodstuff is cooled down for stabilization.

Need 2d& 3d snack products machine which is capacity 250-300 kg

I am interested in corn flakes manufacturing complete line.

Kindly get in touch.

I am from INDIA

I am interested in corn flakes manufacturing complete line.

Kindly get in touch.

Dear sir/madam

Could you please provide me with the recipe of the 2D snack pellets like bugles?

thanks

Hi

Does your bread crumb machine do caramel?

we are interested in Pet Food Extruder Machine With Twin-Screw and also with Metal Detector — For Making Dog Food, Cat Food or Fish Feed. Kindly send us the quote