Why choose Hiwant pet food extruder for manufacturing pet feed

Food extrusion cooking professionals are stepping up to assist pet feed suppliers stay on peak of challenges like high-meat and different component recipes, and satisfying and outperforming progressively specific pet feed safety rules.

Pet feed suppliers are attempting to remain on peak of business changes including high-meat and various component recipes, and satisfying and outperforming progressively specific pet feed safety rules are just a couple of the problems they are dealing with. The good thing is, food extrusion cooking professionals are taking the initiative to assist suppliers guarantee their dreams are fulfilled.

Hiwant are undoubtedly finding many more natural pet feed formulations being delivered to the marketplace.Pet feeds are being developed with much higher meat component, less grain content and different plant protein additions.While pet feed suppliers develop their pet feed formulations, extrusion cooking specialists are assisting them get manufacturing changes expected for various drying properties.

From a drying process view, high-meat component pet feed is rather harder to deal with.They generally need more time to preserve. As soon as fresh recipes change pet feed drying properties, clients with established drying machines will observe lessens in manufacturing rates on this kind of pet feed. Nowadays there are approachs that can be found to enhance productivity, and yet the relationship between power-effective drying and output will turn out to be more

complicated. Clients desire to easily control the amount of wetness in the drying machine to get rid of condensation and as productive as possible

Hiwant has furthermore moved up to the challenge of high-degree meat content , and also enhancements in cooling modules engineering technology (specifically for the high-wetness TSP applied in moist and tinned pet feeds) and feed unit engineering technology.The feed unit engineering technology enhancements target particularly upon challenging to add in supplements that could be very light-weight in mass density.Progressively high degrees of meat content in pet feed have motivated fresh drying technology designs.

Pet feed health and safety has consistently been a main challenge of pet feed suppliers,our company is focusing tightly on pet feed manufacturers to comprehend their own requirements while we create the newest pet feed drying machine. Our comapny is asking quite particular questions, not merely about their requirements, but about the needs of their shoppers.

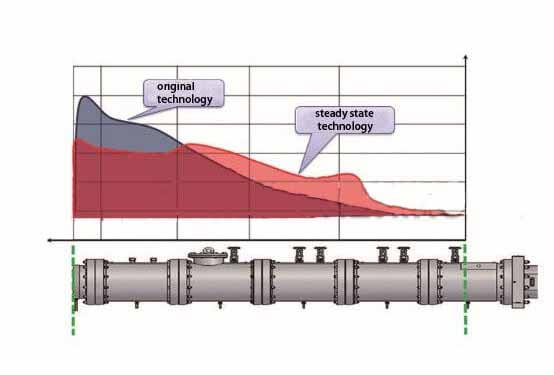

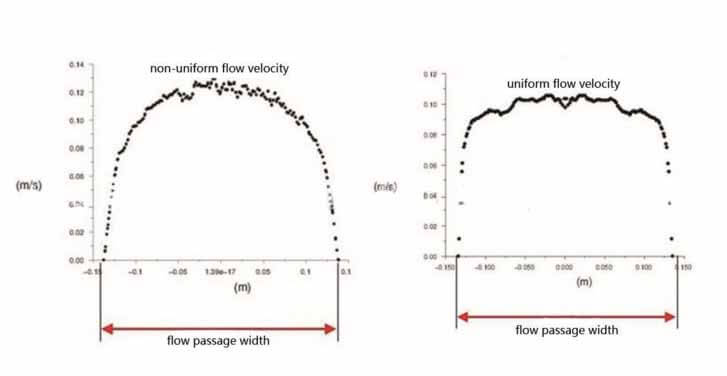

In generally, manufacturers demand technology assistance that includes unique pet feed production requirements, from the maintanence of production line to the drying effects on pet feed . To satisfy these kinds of requirement, Hiwant has expanded its programs service team with the addition of foodstuff expert and microbiologists to offer advice on line development and its influence on processing and feed health and safety.These scientific options consider the organic, chemical and physical risks in feed production which may cause a final pet feed to be dangerous.Sterilization treatments are a crucial factor on pet feed extrusion process. One example is, Hiwant designed flow valve deliver the manufacturers of pet feed and fish feed with a further hygienic need and risk-free extrusion cooking process.

Need 2d& 3d snack products machine which is capacity 250-300 kg

I am interested in corn flakes manufacturing complete line.

Kindly get in touch.

I am from INDIA

I am interested in corn flakes manufacturing complete line.

Kindly get in touch.

Dear sir/madam

Could you please provide me with the recipe of the 2D snack pellets like bugles?

thanks

Hi

Does your bread crumb machine do caramel?

we are interested in Pet Food Extruder Machine With Twin-Screw and also with Metal Detector — For Making Dog Food, Cat Food or Fish Feed. Kindly send us the quote